At Wintergreen Northern Wear, every stitch tells a story. Since 1989, we’ve been handcrafting clothing in Ely, Minnesota, designing, cutting, sewing, inspecting, and selling under one roof. In an era where much of the apparel industry has moved overseas, we remain proudly USA-made. We combine modern precision tools with old-school craftsmanship to create gear rugged enough for Arctic expeditions yet refined enough for daily wear.

Why “Made in Minnesota” Still Matters

Producing in Minnesota means more than a label. It means accountability, ethical labor, local jobs, and total control over quality. It allows us to innovate quickly, repair or adjust garments later, and maintain a consistency that’s nearly impossible in outsourced models. It also allows us to connect directly with the people who wear our gear, many of whom visit our Ely store to see where it’s all made.

When you purchase Wintergreen, you’re supporting a Northern Minnesota economy of skilled craftspeople. Each garment embodies decades of expertise, a dedication to heritage, and a tangible link between maker and wearer. This community connection is part of why our customers often say their Wintergreen gear “feels different” than mass-produced outerwear.

Our Design DNA

Our pieces are inspired by two things: wild places and our Scandinavian heritage. The Boundary Waters Canoe Area Wilderness (BWCA), Arctic expeditions, and snowy northern forests have shaped our functional designs, while Scandinavian sensibilities influence the clean, timeless style. The result? Garments that move seamlessly from backcountry ski trails to everyday winter commutes.

Wintergreen’s founder, Susan Hendrickson-Schurke, started the business in 1989 with a clear vision: build clothing that could withstand the coldest expeditions yet still look and feel right for daily life. That balance of expedition-ready function and approachable style continues to guide us today.

The Build: Precision Meets Craft

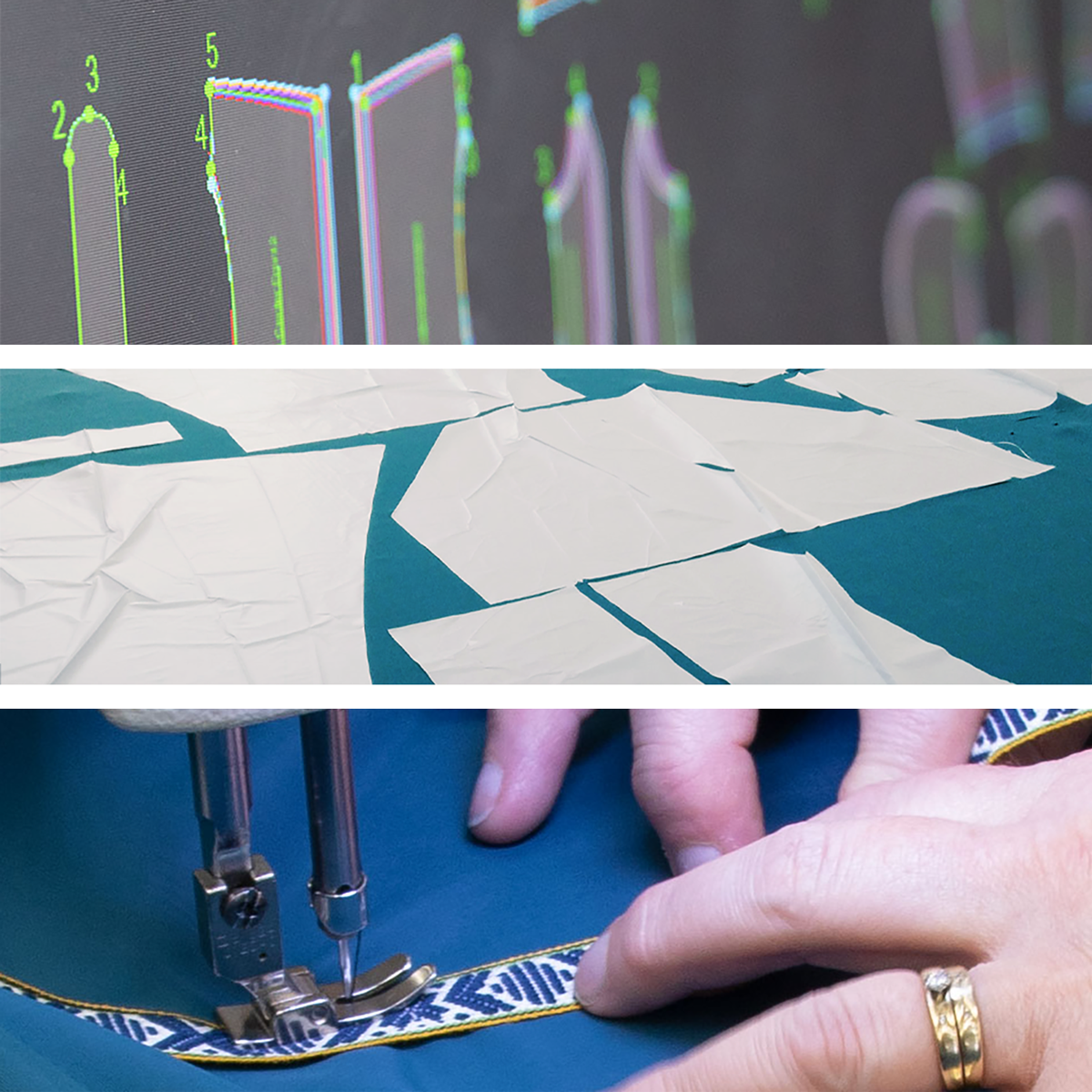

We oversee every step of the process, ensuring unmatched quality and durability:

-

Digital patterns for precision: We create patterns digitally for exact control and fast edits, improving fit consistency and minimizing waste. This method allows us to adjust quickly when we innovate new designs or refine existing ones.

Digital cutting for accuracy: Our cutting machine ensures accuracy, while allowing us to spot flaws in the fabric before production begins. This step significantly reduces waste and ensures customers never see compromised fabric quality. -

Single-technician builds: Each garment is sewn from start to finish by one skilled craftsperson—not divided into piecework. With ~10–12 sewers on our team, every product carries the pride of an individual maker. This approach means errors are caught earlier, and every stitch is sewn with accountability.

-

Quality gatekeeping: Every garment is inspected by our production manager before heading to the Ely store floor or shipping department. Details like reinforced seams, secure stitching, and perfect alignment are checked—because good enough is never enough.

What End-to-End Control Enables

By managing the entire chain—design, cut, sew, inspect, sell—we offer consistency you can trust. Fit is reliable, improvements can be made quickly, and dependable repairs are always possible. This end-to-end model, once standard, is now rare in apparel. For us, it’s non-negotiable.

This approach also means your feedback matters. When customers or expedition guides share field insights, we can incorporate improvements into the next production cycle. That agility is nearly impossible for brands that outsource manufacturing overseas.

Field-Tested Proof

Wintergreen garments aren’t just theory. They’ve been worn on expeditions to the Arctic, the Antarctic, and countless wilderness adventures in between. National Geographic explorers, polar guides, and everyday Minnesotans alike have trusted Wintergreen gear to keep them warm and protected.

Take our anoraks: tested against whiteout winds and deep snow, they provide unmatched performance while remaining lightweight and breathable. Or our pants, crafted to move comfortably whether you’re skiing across frozen lakes or simply shoveling your driveway. Our fleece midlayers have become staples for layering systems used by adventurers from pole to pole.

Built to Last

We don’t make fast fashion. We make heirloom-quality gear. With care, a Wintergreen garment can last for decades—many customers still wear pieces purchased in the ’90s. Our focus is durability, repairability, and sustainability.

When seams need reinforcement or a zipper eventually wears out, we can repair your garment right here in Minnesota. This commitment to long-term service makes Wintergreen not just a purchase but a partnership.

Sustainability Through Longevity

Every garment we make is designed to be used, repaired, and passed down. By building clothing that lasts decades, we reduce waste and avoid the “buy, toss, replace” cycle that dominates fast fashion. Choosing Wintergreen means choosing gear that aligns with a more sustainable way of living.

A Day in the Workshop

Walk into our Ely workshop and you’ll hear the hum of sewing machines, the precision slice of the cutting table, and the careful attention of craftspeople focused on details. Each sewing technician’s station is their domain, with tools laid out neatly, fabric carefully pinned, and garments slowly taking shape from flat pieces into durable outerwear. It’s not an assembly line—it’s a community of makers, each taking pride in a complete creation.

Visit Us in Ely

Our Ely store isn’t just a retail space—it’s part of the story. Customers can see garments fresh from the workshop floor, meet the people behind the stitching, and experience firsthand what “Made in Minnesota” truly means. If you’re ever in northern Minnesota, we invite you to stop by and connect with our team.

FAQ: Our USA-Made Process

Q: Where are Wintergreen garments made?

A: Every item is handcrafted in Minnesota, primarily in our Ely workshop, with the support of a small network of local sewers.

Q: Why use single-technician sewing instead of piecework?

A: It ensures accountability and quality—one technician oversees an entire garment, checking for flaws as they go.

Q: Do you offer repairs or adjustments?

A: Yes. Because we design and build in-house, we can repair, adjust, and extend the life of your garment.

Q: What’s different about digital patterning and cutting?

A: Digital patterning provides precision and easy edits, while digital cutting ensures accuracy.

Q: How long will a Wintergreen garment last?

A: With proper care, decades. Many of our products are still in active use 20–30 years after purchase.

Q: Can I visit the Ely store?

A: Absolutely. Our Ely store showcases our full line of garments, fresh from the workshop, and gives you a chance to connect with the makers themselves.

When you choose Wintergreen, you’re investing in a process that honors craftsmanship, community, and the wilderness that inspires us. Proudly USA-made—designed, cut, sewn, and sold in Minnesota since 1989.